Servo Drives Explicados: O Que Você Precisa Saber para um Controle de Movimento Ótimo

DANIEL GOMES | |

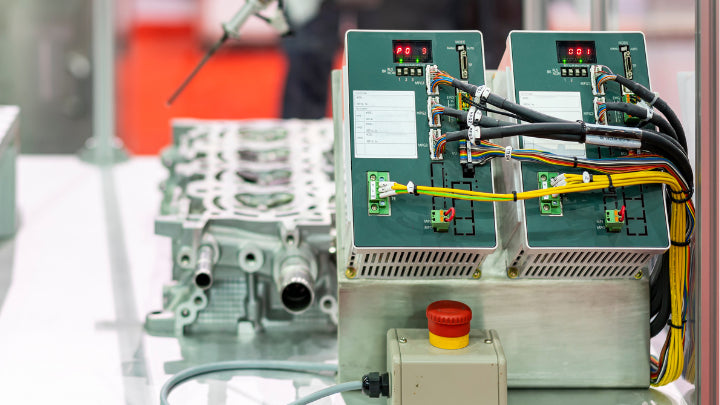

Os Servo Drives Industriais são dispositivos sofisticados projetados para aprimorar a automação controlando motores elétricos em aplicações precisas e de alto desempenho. Aqui está uma análise aprofundada de seus principais recursos, funcionalidade, tipos, aplicações e marcas importantes:

Principais recursos e funções

- Controle de Posição, Velocidade e Torque : Servo drives são capazes de controlar parâmetros do motor até um grau fino. Eles interpretam sinais de um controlador, ajustando a saída do motor para posicionamento exato, regulação de velocidade e aplicação de torque.

- Mecanismo de Feedback : Eles trabalham com sistemas de feedback, como codificadores ou resolvers, para monitorar a posição do motor e ajustar em tempo real. Este loop de feedback é essencial em aplicações que exigem precisão.

- Resposta dinâmica : os servoacionamentos respondem rapidamente às mudanças, o que os torna ideais para operações em que os motores precisam de aceleração, desaceleração ou mudanças de direção rápidas.

- Programabilidade : servo drives avançados podem ser configurados e programados para aplicações específicas, geralmente com software de fácil utilização. Essa personalização ajuda a otimizar o drive para os requisitos do motor e da aplicação.

- Eficiência energética : os servossistemas geralmente oferecem economia de energia, pois usam energia com base nos requisitos de carga e mantêm a eficiência em uma variedade de velocidades de operação.

Tipos de servoacionamentos

- Servo drives CA : Projetados para motores CA, esses drives são adequados para aplicações de alta potência em setores como embalagens e automotivo.

- Servo drives CC : usados com motores CC, são comumente encontrados em aplicações que exigem menos potência e mais controle de torque, embora sejam menos comuns em aplicações industriais modernas.

- Servodrives sem escovas : proporcionam controle preciso sem as necessidades de manutenção associadas às escovas, ideais para tarefas industriais contínuas ou pesadas.

- Servodrives de passo : são especializados para motores de passo, oferecendo alta precisão para tarefas que exigem posicionamento exato, mas normalmente não exigem alta velocidade.

Aplicações

Os servoacionamentos são indispensáveis em muitos sistemas automatizados e robóticos, incluindo:

- Robótica : Controle de braços robóticos, articulações e efetores finais com alta precisão e velocidade.

- Máquinas CNC : essenciais em fresamento, corte e outras operações CNC onde precisão e repetibilidade são cruciais.

- Sistemas de transporte : gerenciamento de velocidade e posições de parada em linhas de montagem.

- Embalagem e etiquetagem : Usado em sistemas que exigem ações rápidas e repetíveis, como em linhas de embalagem.

- Máquinas têxteis : para processos como tecelagem e corte, onde é necessário controle de movimento sincronizado.

- Impressão : Possibilitando manuseio de papel e materiais em alta velocidade e com controle de precisão.

Marcas e modelos líderes

- Siemens : conhecida por sua série SINAMICS, que oferece suporte a aplicações em todos os setores com opções para motores CA e CC, conhecida pela confiabilidade e integração com sistemas de automação Siemens.

- Allen-Bradley (Rockwell Automation) : A série Kinetix oferece excelentes opções de servoacionamentos compatíveis com diversas aplicações industriais, particularmente com integração de CLP.

- Lenze : Oferece servoacionamentos de alta qualidade projetados para eficiência energética e flexibilidade, frequentemente usados em máquinas de embalagem e têxteis.

- Schneider Electric : Conhecidos por sua série Lexium, os servoacionamentos Schneider são compactos, eficientes e adequados para aplicações que exigem precisão no controle de movimento.

- Mitsubishi Electric : A série MELSERVO oferece opções de alta velocidade e alta precisão para automação industrial e tem ampla compatibilidade de integração.

Considerações ao selecionar um servo drive

- Requisitos de aplicação : determine o controle necessário (velocidade, torque, posição), tipo de carga e ambiente.

- Compatibilidade do motor : certifique-se de que o inversor seja compatível com seu tipo de motor e capacidade de carga.

- Requisitos de feedback : decida se você precisa de feedback por meio de codificadores, resolvedores ou outros sensores.

- Recursos de segurança : procure acionamentos com opções de segurança integradas, como recursos de desligamento seguro de torque (STO), parada segura ou parada de emergência.

- Programação e integração : avalie a facilidade de programação do inversor e a compatibilidade com sistemas de automação ou PLC existentes.

Considerações finais

Para indústrias que visam aumentar a produtividade e a precisão, servo drives industriais são inestimáveis, oferecendo controle de alta velocidade e minimizando erros em sistemas automatizados. Selecionar o drive certo envolve considerar não apenas a compatibilidade do motor, mas também o nível de controle, feedback e personalização necessários para sua aplicação específica.

Se você precisar de conselhos sobre como selecionar um servoacionamento para um uso específico ou comparar marcas, ficarei feliz em fornecer recomendações adicionais com base na sua aplicação.

- Industry Trends

Marcado em