Understanding FANUC Servo Drives: Key Features & Benefits

DANIEL GOMES | |

Understanding FANUC Servo Drives in CNC Systems

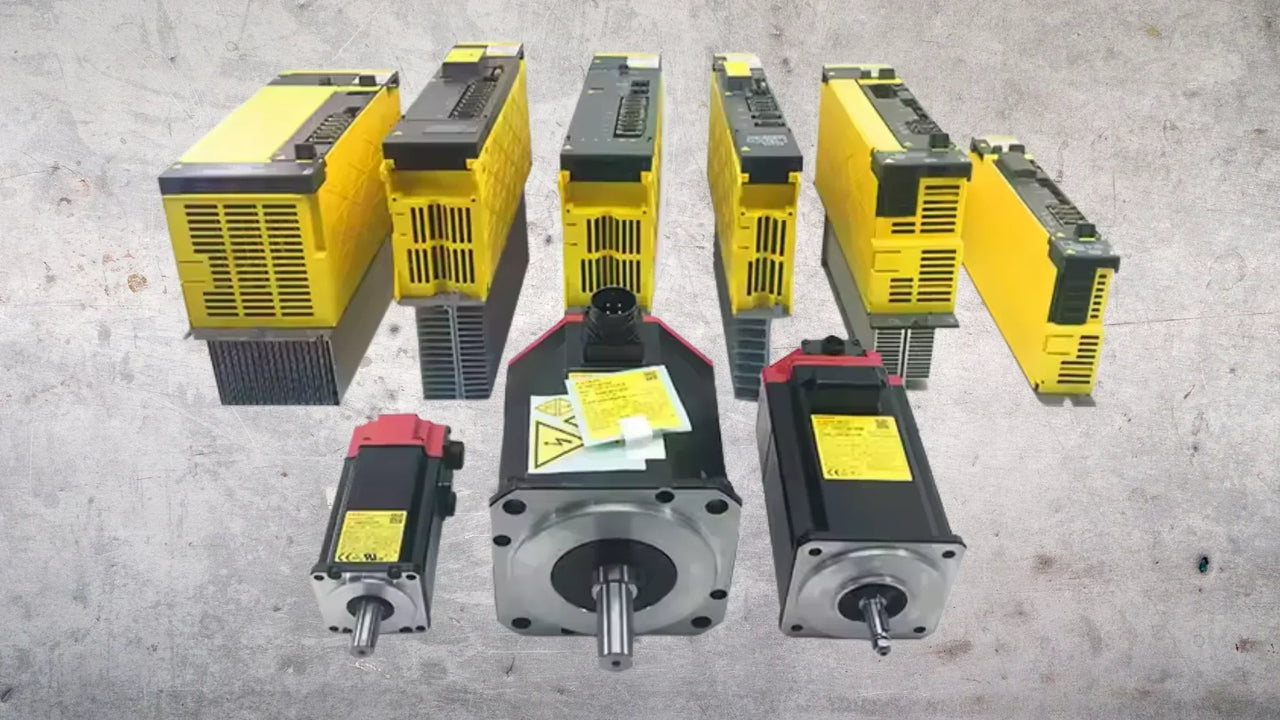

FANUC servo drives—also called amplifiers or drivers—are key components in CNC machines and industrial automation. These drives regulate motion with precision and are essential for milling machines, robotic arms, lathes, and factory lines powered by FANUC CNC controls.

🔍 What Does a FANUC Servo Drive Do?

The drive receives commands from the CNC controller and amplifies them to deliver controlled speed, torque, and position to the servo motor. It continuously adjusts based on encoder feedback, ensuring real-time accuracy during operations.

🔧 Popular FANUC Drive Models Available

You can find these and other models on our platform:

-

A06B-6080-H303 – Servo amplifier unit, widely used in older CNC systems

-

A06B-6117-H209 – Alpha i-series drive, suitable for advanced FANUC CNC machines

These models are trusted for their reliability, ease of replacement, and compatibility with a wide range of FANUC equipment.

✅ Benefits of FANUC Servo Drives

-

High Performance: Real-time motor feedback ensures exact positioning, crucial in CNC applications.

-

Reliability: Built for 24/7 operation in demanding environments.

-

Compact & Modular: Simplifies integration and servicing.

-

Error Diagnostics: Built-in alarms for quick troubleshooting.

⚠️ Common Alarms and Troubleshooting Tips

FANUC drives use display codes to signal faults. Understanding these codes helps minimize downtime.

Common Alarm Codes:

-

8, 9, or A: Short circuit or excessive current in one of the motor phases.

-

5 or 6: Overheating or feedback issues.

-

1–3: Power input problems or improper wiring.

Troubleshooting Checklist:

-

Disconnect and inspect encoder cables.

-

Remove U/V/W motor cables and test again.

-

Check for correct jumper settings and connector wiring.

🛠 When to Replace Your FANUC Drive

If troubleshooting doesn’t resolve the error or the unit shows signs of internal failure (like burnt IGBTs or capacitor leakage), replacement is likely required. Always match the part number and check CNC system compatibility.

🔍 Frequently Asked Questions (FAQ)

What is a FANUC servo drive used for?

A FANUC servo drive controls motor speed, torque, and positioning in CNC machines and automation systems by amplifying controller signals with real-time feedback.

How do I troubleshoot common FANUC alarm codes?

Disconnect encoder and motor cables, inspect jumper settings, and test circuits phase by phase to isolate issues like OD or overheating faults.

Are these drives compatible with all CNC machines?

Compatibility depends on the CNC controller and axis requirements. Always match the model number—like A06B-6080-H303 or A06B-6117-H209—to your FANUC control system.

When should I replace a servo drive rather than repair it?

If IGBTs, capacitors, thermal sensors, or other internal components fail diagnostics—even after resets—replacement is generally recommended.

Where can I buy a reliable FANUC servo drive?

At ddpartssolution, we specialize in OEM, surplus, and reconditioned FANUC drives, backed by experience, quality testing, and fast global shipping.

✅ About Our Expertise

At ddpartssolution, we bring years of hands-on experience in sourcing, inspecting, and distributing industrial automation equipment, including FANUC servo drives and amplifiers. Our team understands the technical demands of CNC systems and works daily with technicians, integrators, and maintenance professionals across industries.

We pride ourselves on:

-

Experience: Thousands of FANUC parts shipped globally, tested and verified.

-

Expertise: Deep knowledge of servo systems, drive faults, and CNC integration.

-

Authoritativeness: Trusted by manufacturers, automation engineers, and resellers worldwide.

-

Trustworthiness: Fast quotes, clear communication, and transparent product listings.

Looking for a specific model or need help choosing the right drive for your system? Our team is ready to help.

📦 Conclusion

FANUC servo drives are the backbone of precision CNC automation. Whether you're operating older Alpha series systems or modern i-series controls, knowing how these amplifiers work—and how to replace them—keeps your operation running smoothly.